KlettGlueing

Connection for sensitive parts

Low binding force

Low temperature process

A surface has a NanoWiring structure

Use of low viscosity adhesive

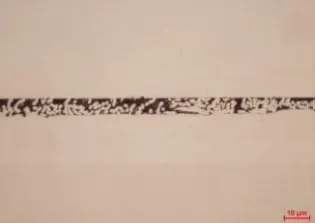

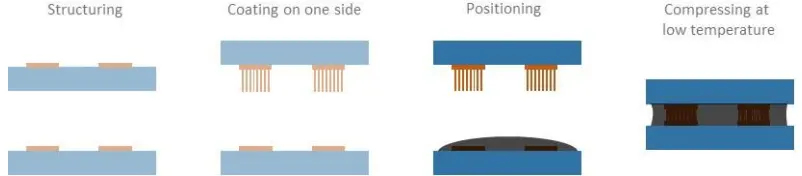

KLETTGLUEING PROCESS

How We Manufacture KlettGlueing

Structuring

Coating

One surface has a NanoWiring structure

Positioning

Applying adhesive

Compressing

Low temperature

Pressure from 1 MPa

Time from 60 ms

KLETTGLUEING OVERVIEW

KlettGlueing Applications

Assembly joints - FPC/PCB, PCB/PCB

Temperature sensitive devices

Fragile equipment

KlettGlueing Video Tutorial

Watch video about KlettGlueing presented by our CEO

KLETTGLUEING+ PROCESS

KlettGlueing+ Features

Lowest preparation effort

Low binding forces

Repairable

KlettGlueing+ Applications

Assembly joints - FPC/PCB, PCB/PCB

Temperature sensitive devices

Fragile equipment

Prototypes

Connection repair

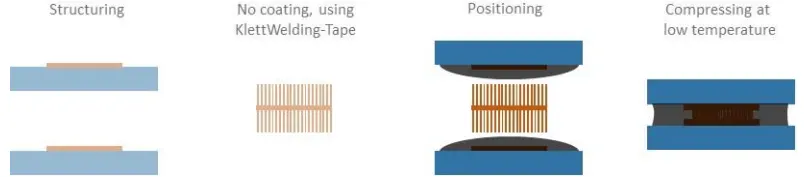

How We Manufacture KlettGlueing+

Structuring

Coating

No surface has a NanoWiring structure

Positioning

Apply adhesive

Compressing

Low temperature

Pressure from 1 MPa

Time from 60 ms

Comparison of NanoWired connection technologies

The following table shows the comparison between KlettWelding and KlettWelding+

Comparison Table

KlettGlueing

KlettGlueing+

NanoWiring

one side + adhesive

KlettWelding Tape + adhesive

Process Temperature (°C)

20...150

20...150

Process Pressure (MPa)

1...5

1...5

Process Time (s)

0.06...300

0.06...300

Shear strength (MPa)

approx. 20

approx. 20

Main Advantage

- Low temperature

- Low pressure

- Only one NW level

- Very fine pitch

- Low pressure

- Only one NW level

- Very fine pitch

- Low temperature

- Low pressure

- No NW level

- Low pressure

- No NW level

Typical Application

- FPC/PCB, PCB/PCB

- Temperature sensitive devices

- Fragile equipment

- Temperature sensitive devices

- Fragile equipment

- FPC/PCB, PCB/PCB

- Temperature sensitive devices

- Fragile equipment

- Prototypes

- Connection repair

- Temperature sensitive devices

- Fragile equipment

- Prototypes

- Connection repair