KlettSintering

Robust substrates, strong connection

Most cost-effective method

Only one surfaces have a NanoWiring structure

Shear strength up to 60 MPa

Significantly higher tensile strength than KlettWelding

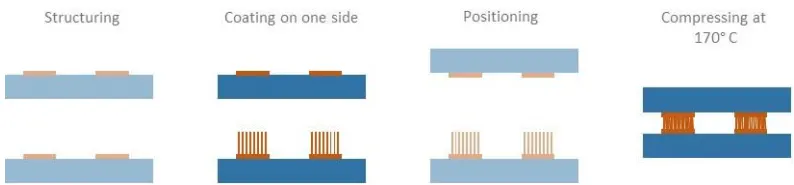

KLETTSINTERING PROCESS

How We Manufacture KlettSintering

Structuring

Coating

One surface has a NanoWiring structure

Positioning

Compressing

From 170°C

Pressure from 10 MPa

Time from 10 s

KLETTSINTERING OVERVIEW

KlettSintering Applications

Automotive busbar Power transport by car/plane/truck

Housing technology

Power Electronics / Die Attach

Contact link

Ceramics on metal (e.g. sensors)

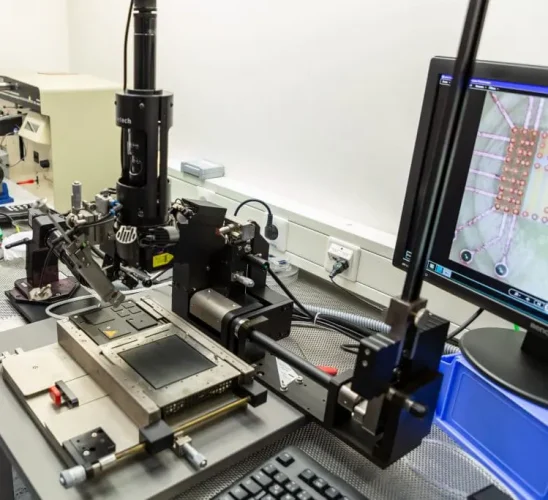

KlettSintering Video Tutorial

Watch video about KlettSintering presented by our CEO

KLETTSINTERING+ PROCESS

KlettSintering+

Minimum preparation effort

No surface has NanoWiring structure

Use of KlettWelding Tape

High-strength, repairable

KlettSintering+ Applications

Highest flexibility application

High current busbars

3D electronics

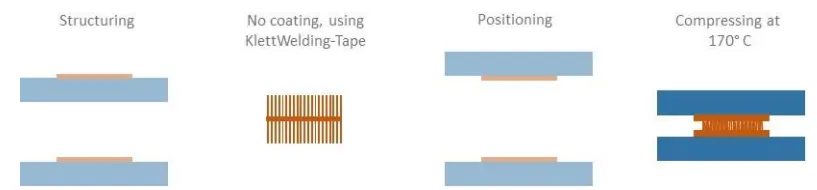

How We Manufacture KlettSintering+

Structuring

Coating

No surface has NanoWiring structure

Positioning

Compressing

From 170°C

Pressure from 10 MPa

Time from 120 s

Comparison of NanoWired connection technologies

The following tables shows the comparison between KlettSintering and KlettSintering+ connection technologies.

KlettSintering

KlettSintering+

NanoWiring

One Side

KlettWelding Tape

Process Temperature (°C)

170...240

170...240

Process Pressure (MPa)

10...30

10...30

Process Time (s)

120...300

120...300

Shear Strength (MPa)

20...50

30...60

Main Advantage

High shear strength

Very fine pitch

Only one NW level

Very fine pitch

Only one NW level

No NW stage

High shear strength

High shear strength

Typical Application

Die Attach

Flip Chip

Flip Chip

Die Attach

Flip Chip

High current busbar

Flip Chip

High current busbar