KlettWelding

The metallic Velcro fastener

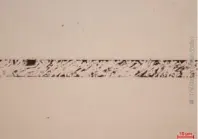

Both surfaces have a NanoWiring structure

Shear strength up to 60 MPa

Resulting bond has electrical and thermal characteristics comparable to bulk metal

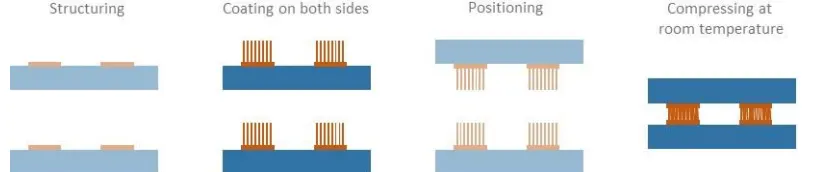

KLETTWELDING PROCESS

How We Manufacture KlettWelding

Structuring

Coating

Both surfaces have a NanoWiring structure

Positioning

Compressing

Room temperature

Pressure from 15 MPa

Time from 60 ms

KLETTWELDING OVERVIEW

KlettWelding Applications

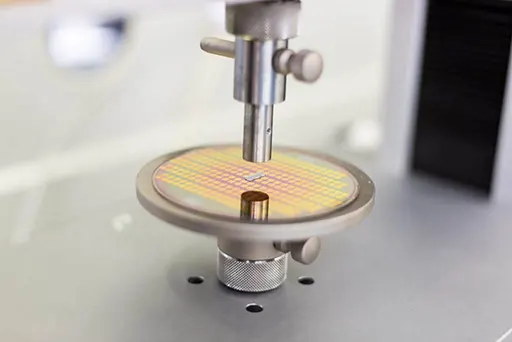

Flip chip

Semiconductor production

Assembly joints - FPC/PCB, PCB/PCB

Plastic connections

Die Attach

Temperature sensitive devices

KlettWelding Video Tutorial

Watch video about KlettWelding presented by our CEO

KLETTWELDING+ PROCESS

KlettWelding+

Highest connection strength

Both surfaces have a NanoWiring structure

KlettWelding Applications

Die attach

Flip chip

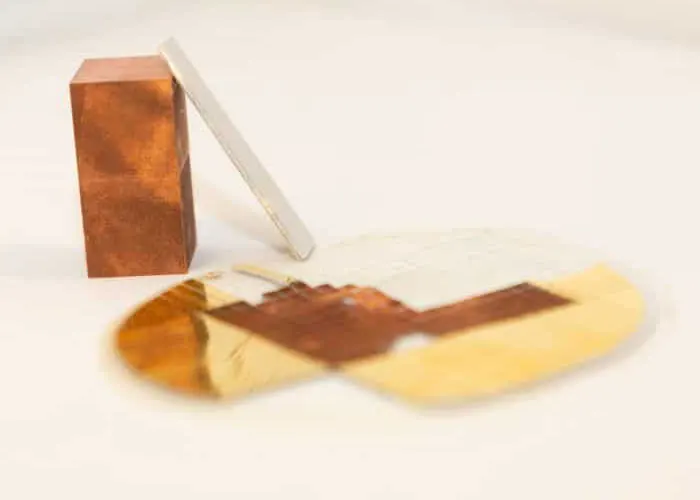

High current busbars

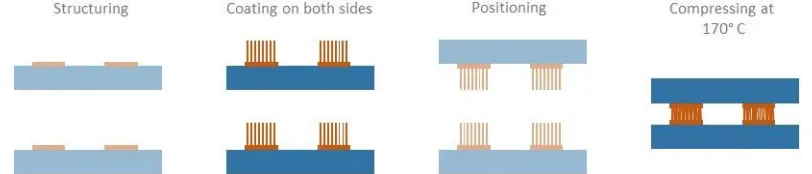

How We Manufacture KlettWelding+

Structuring

Coating

Both surfaces have a NanoWiring structure

Positioning

Compressing

From 170°C

Pressure from 10 MPa

Time from 10 s

Comparison of NanoWired connection technologies

The following tables shows the comparison between KlettWelding and KlettWelding+ connection technologies

KlettWelding

KlettWelding+

NanoWiring

Both Sides

Both Sides

Process Temperature (°C)

20

170...240

Process Pressure (MPa)

From 15

From 10

Process Time (s)

0.06...60

120...300

Shear Strength (MPa)

6...20

20...65

Main Advantage

Very fast

Very fine pitch

Low temperature

Very fine pitch

Low temperature

Very fine pitch

Very high shear strength

Very high shear strength

Typical Application

Die Attach

Flip Chip

Temperature sensitive devices

Flip Chip

Temperature sensitive devices

Die Attach

Flip Chip

High current busbar

Flip Chip

High current busbar