The most efficient connecting technology

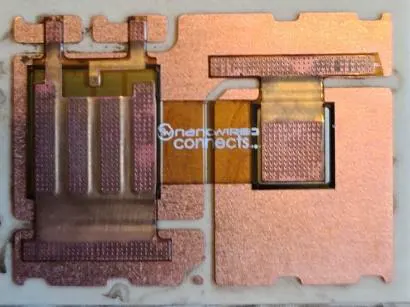

Bond any metallic or metallized surface

Breakthrough value propositions

Germany based, award winning company

50+ patents

Company-owned technology centers in Europe and Asia

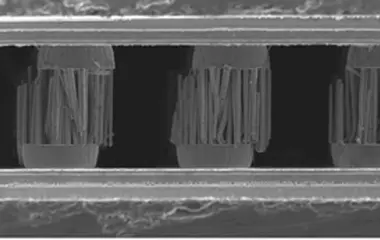

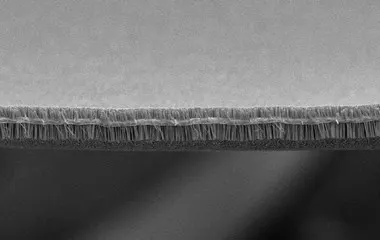

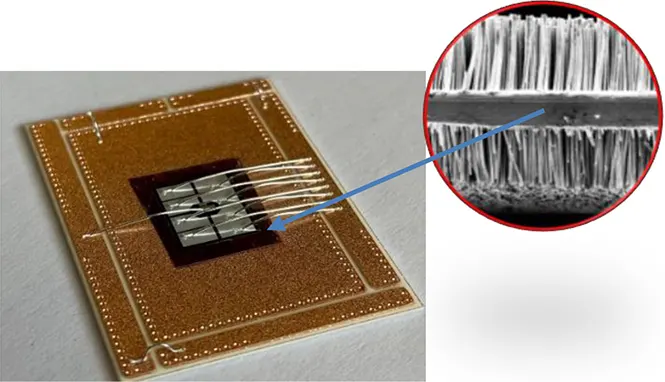

NanoWired Connection Technologies

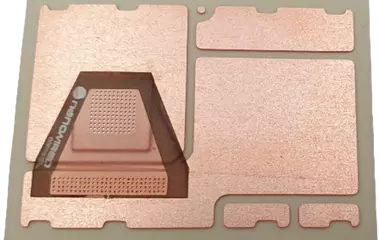

We research and develop substitution of solder, silver/copper sintering, TLPS, brazing, thermal connections, busbars.

NanoWired High Performance Applications

ADVANCED TECHNOLOGY

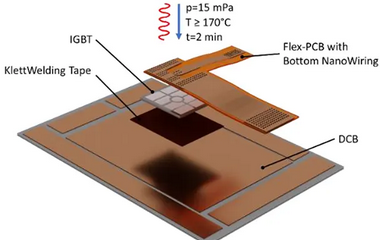

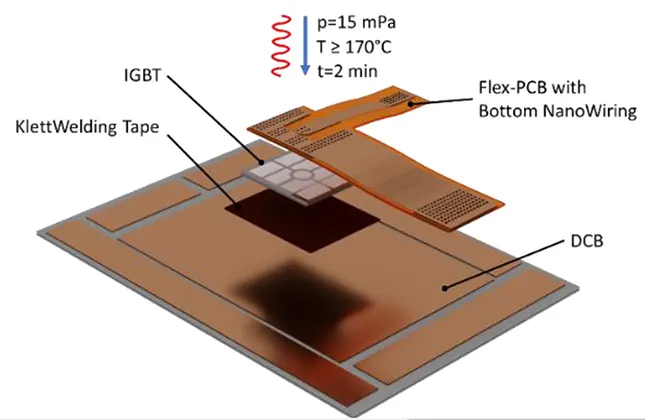

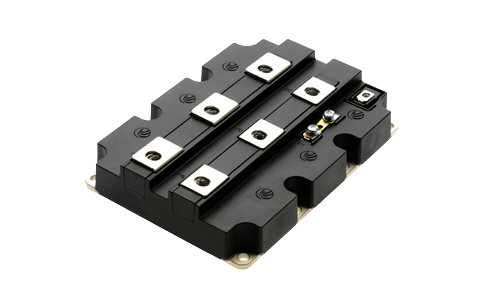

Discover a Way to Manufacture200°C Power Module

No Printing/Dispensing.

No Drying/Cleaning.

Low temperature process.

No CTE mismatch.

Top/bottom interconnection in one step.

MADE BY NANOWIRED TEAM

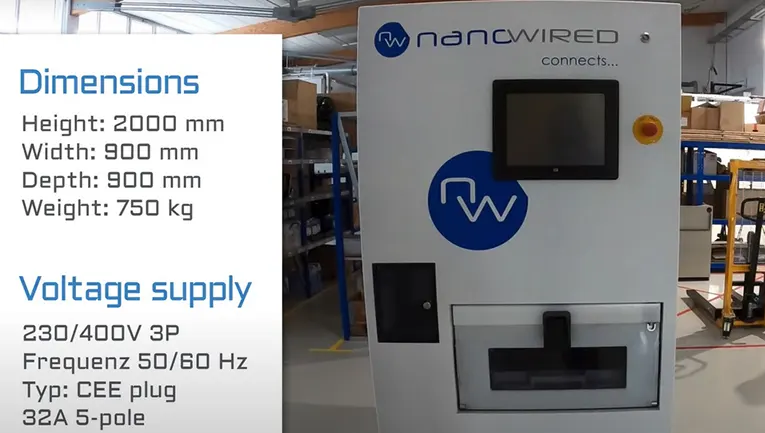

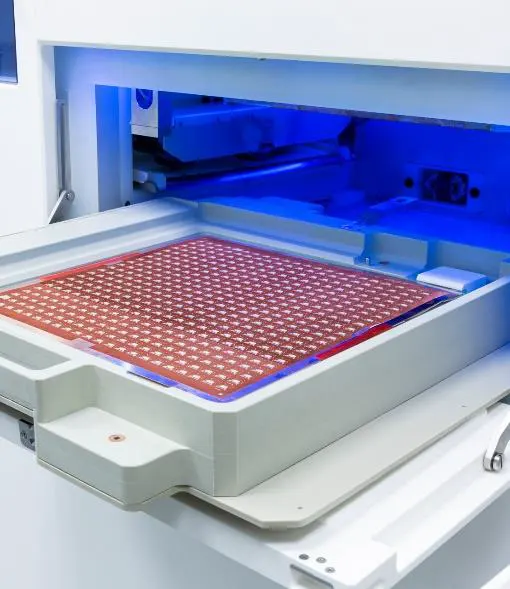

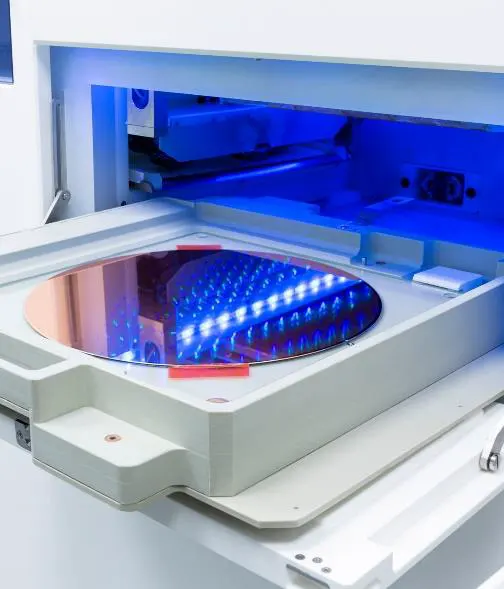

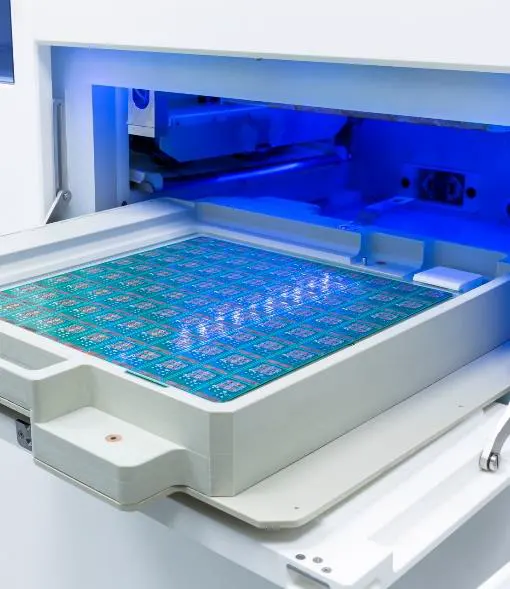

NanoWired presents the unique, patented NanoWiring Cube!

Original NanoWiring in your facility!

Fully automatic process.

Intelligent drawer to placing the substrate.

Integrated touch display.

Production area 400*300 mm.

Max substrate height 120 mm.